When it comes to the demanding conditions of a mechanic's workshop, especially those frequently exposed to moisture, Flashlights For Mechanics are more than just an accessory—they are essential tools for ensuring safety and efficiency. The best models offer robust construction with waterproof seals and impact-resistant bodies made from materials like aircraft-grade aluminum, featuring a hard-anodized finish for durability and grip. High-intensity LED lights provide ample brightness with adjustable focus and multiple light settings to handle various tasks. A minimum IP67 rating guarantees protection against water immersion, making these flashlights suitable for the toughest conditions. To maintain their performance, it's crucial to dry them thoroughly after use, inspect and replace O-rings and seals regularly, store them properly, and manage batteries responsibly to extend their lifespan and reliability. By investing in well-maintained Flashlights For Mechanics with these features, mechanics can trust their tools to deliver clear visibility and consistent performance when it matters most.

When precision is paramount, and conditions are far from ideal, waterproof flashlights for mechanics stand as indispensable tools in automotive and mechanical workshops where wetness is a constant companion. This article illuminates the critical role these flashlights play, delving into their key features, top-rated models, scientific underpinnings of their construction, practical applications, and tips for selecting the most durable and bright options to enhance visibility and safety in damp environments. Mechanics rely on dependable light sources to navigate complex tasks, and understanding how to choose the best waterproof flashlight is essential for maintaining productivity without compromising on quality or longevity.

- Understanding the Importance of Waterproof Flashlights in Automotive and Mechanical Workshops

- Key Features to Look for in Flashlights for Mechanics

- Top-Rated Waterproof Flashlights for Mechanics: A Comprehensive Review

- The Science Behind Waterproofing in Flashlights: Materials and Techniques

- Practical Applications of Waterproof Flashlights in Wet Conditions

- Maximizing Durability and Brightness: Tips for Selecting the Best Waterproof Flashlight

- Maintenance and Care for Your Mechanic's Waterproof Flashlight: Ensuring Longevity and Performance

Understanding the Importance of Waterproof Flashlights in Automotive and Mechanical Workshops

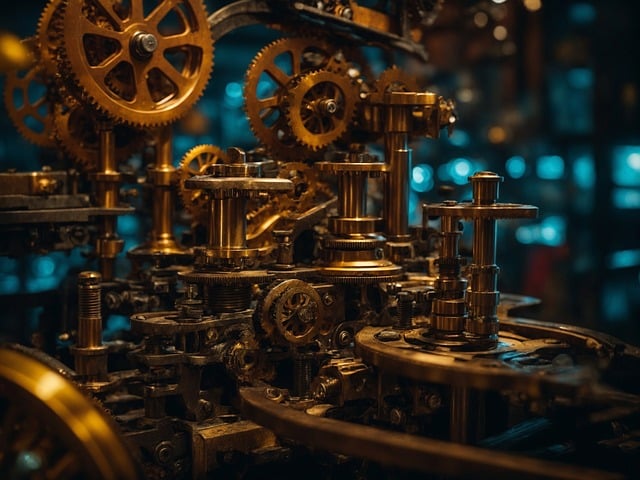

When it comes to automotive and mechanical workshops, reliability and functionality are paramount. These environments are often rife with oil, grease, water, and other substances that can compromise the performance of standard lighting solutions. This is where flashlights for mechanics designed to be waterproof play a critical role. Their ability to withstand liquid exposure ensures that light sources remain operational even in the wettest conditions. Mechanics need illumination that won’t fail them when they’re under the hood of a car, checking tight spaces, or working in areas where accidental splashes are inevitable. A waterproof flashlight doesn’t just protect against direct water immersion; it also safeguards against condensation and humidity that can fog up standard lights and reduce visibility. Incorporating waterproof flashlights into the arsenal of tools for automotive and mechanical workshops is not just a smart choice for maintaining optimal working conditions—it’s an essential safety measure that enhances both precision and efficiency in the demanding field of vehicle repair and maintenance. The durability of these lights means that they can be used repeatedly without the risk of electrical failure due to moisture, ensuring that mechanics have a consistent and dependable light source at all times.

Key Features to Look for in Flashlights for Mechanics

When selecting a flashlight for mechanic tasks, particularly in wet workshop conditions, certain features stand out as crucial for ensuring both safety and efficiency. A high-quality waterproof flashlight for mechanics should be durable enough to withstand harsh environments, including exposure to water, oil, and dust. The construction material, often rugged aluminum alloys or high-impact plastic, contributes to the flashlight’s longevity and resistance to damage from drops or impacts. Waterproofing is a non-negotiable feature, with an IP (Ingress Protection) rating of at least IP67 being highly recommended. This rating indicates that the flashlight can be submerged in one meter of water for up to 30 minutes without any moisture ingress.

Beyond waterproofing, mechanics should prioritize flashlights with a robust and focused beam, preferably with multiple modes to suit different working conditions. A high-lumen output provides exceptional brightness for illuminating dark corners or complex tasks, while lower settings conserve battery life for longer operational use. LED technology is preferred due to its long lifespan and energy efficiency. Additionally, a strobe function can be useful for signaling in emergency situations. The beam type should be adjustable between flood and spot options, allowing mechanics to switch between a broad illumination for larger areas and a tight beam for fine detail work. Lastly, ergonomic design with a non-slip grip is essential for handling the flashlight with wet or oily hands, ensuring that the light remains secure and accessible when it’s most needed. Flashlights for mechanics must be reliable, versatile, and powerful enough to handle any workshop challenge, making them indispensable tools for professionals in this field.

Top-Rated Waterproof Flashlights for Mechanics: A Comprehensive Review

When working under the hood of a car or in a workshop where water and electricity intermingle, mechanics require dependable lighting solutions that can withstand the harsh conditions. Flashlights for mechanics must be rugged, bright, and most importantly, fully waterproof to prevent any electrical malfunction when accidents happen. Top-rated waterproof flashlights are designed to provide reliable illumination in wet and slippery environments, ensuring that the job is completed safely and efficiently. These flashlights are often constructed with high-quality materials such as aerospace-grade aluminum or durable rubber armor, which protects them from drops, dents, and the rigors of daily use. They also feature waterproof seals that lock out moisture without compromising the user’s access to battery compartments and switches. The best models offer lumen outputs that range from spotlight-like beams for long-distance visibility to wider floodlights for close-up tasks. Mechanics can choose from various configurations, including single-cell, AA/AAA, or rechargeable 18650 battery types, catering to the specific needs of their work environment and personal preferences. When selecting a waterproof flashlight for workshop use, it’s crucial to consider the lumen output, beam type, battery type, run time, and impact resistance to ensure that the chosen light source can handle the demands of automotive repair and maintenance.

The Science Behind Waterproofing in Flashlights: Materials and Techniques

In environments where water is a constant presence, such as those encountered by mechanics in workshops, the reliability of a flashlight can be the difference between safe operation and potential hazards. The science behind waterproofing flashlights involves both materials and techniques that safeguard the device against moisture intrusion. High-quality flashlights for mechanics are engineered with advanced materials like rubberized O-rings and gaskets that create watertight seals around the battery compartment and switches. These components, when combined with a durable, hydrophobic outer shell, effectively prevent water from compromising the internal workings of the flashlight. The waterproofing process also employs techniques such as hermetic sealing, where components are placed in an environment with a lower pressure than the ambient atmosphere to remove air and moisture before being assembled. This ensures that no residual air or moisture is trapped inside the device, which could condense and cause corrosion or short circuits over time. Additionally, some flashlights are filled with nitrogen or argon gases, which are inert and displace the regular air, further preventing the formation of water droplets within the unit. The commitment to incorporating such materials and employing these precise techniques results in flashlights that not only survive but also perform reliably in wet workshop conditions, making them indispensable tools for mechanics who require clear visibility under challenging circumstances.

Practical Applications of Waterproof Flashlights in Wet Conditions

In environments saturated with moisture, such as automotive workshops or marine settings, reliability on lighting is paramount. Flashlights for mechanics are not just a convenience; they are an indispensable tool in these conditions where waterproof flashlights excel. The integrity of electrical components within a standard flashlight can be compromised by wetness, leading to potential hazards and operational failures. Waterproof flashlights designed for mechanics, however, circumvent this issue, ensuring that the mechanical tasks at hand—be it diagnosing an engine or inspecting undercarriage components in a flooded garage—can proceed without interruption. These devices are constructed with robust materials like rubberized exteriors or sealed o-rings to prevent water ingress, allowing the beam to penetrate through the gloom, illuminating workspaces where puddles and splashes are commonplace. The durability of such flashlights means that mechanics can work with confidence, knowing their light source won’t fail them when they need it most. Additionally, the high-intensity output necessary for close-up tasks is coupled with a focused beam, eliminating the glare that can occur in reflective surfaces and ensuring clarity of vision even in the wettest conditions. This combination of durability, performance, and functionality makes waterproof flashlights an essential tool for any mechanic working in environments where water poses a constant challenge.

Maximizing Durability and Brightness: Tips for Selecting the Best Waterproof Flashlight

When selecting a flashlight for the demanding conditions often encountered in a mechanic’s workshop, durability and brightness are paramount. A robust waterproof flashlight can be the difference between clear visibility and compromised safety. The best models designed for mechanics are engineered with high-impact resistant materials such as aircraft-grade aluminum to withstand repeated drops or accidental knocks without failing. These flashlights often feature a hard-anodized finish that not only protects against scratches but also enhances the grip, which is crucial when working with greasy or oily surfaces.

Brightness is another vital factor for flashlights for mechanics. A high-intensity beam allows for fine detail work without causing blindness or straining the eyes. Look for a flashlight with a lumen output of at least 200 lumens to illuminate dark spaces effectively. Additionally, a beam with a focused hotspot, complemented by a wide peripheral beam, enables mechanics to see both close-up areas and the surrounding workspace clearly. Features like adjustable focus or multiple brightness levels can be particularly useful, as they allow users to adapt the light output to different tasks throughout the day. To ensure longevity and performance, select a flashlight with LED technology, as it offers long-lasting durability and energy efficiency compared to older incandescent bulbs. Waterproof models rated IP67 or higher are ideal, ensuring that the flashlight can withstand temporary immersion in water up to 1 meter for 30 minutes without any harmful effects.

Maintenance and Care for Your Mechanic's Waterproof Flashlight: Ensuring Longevity and Performance

Maintaining a waterproof flashlight, particularly one that is frequently used in a mechanic’s workshop, is crucial for ensuring its longevity and optimal performance. To prevent moisture damage, it’s essential to dry the flashlight after each use, especially if it has been exposed to wet conditions. Mechanics should gently blot any excess water from the exterior with a soft, lint-free cloth and avoid using high-pressure air driers that could force water into the device’s vulnerable points. Regularly inspecting the O-rings and seals for wear and replacing them as needed will maintain the flashlight’s waterproof integrity. Additionally, storing the flashlight in a cool, dry place away from direct sunlight will protect its battery and electronic components.

For prolonged lifespan and consistent illumination, it’s important to manage the battery care of your waterproof flashlight. Choose high-quality alkaline or rechargeable batteries designed for harsh environments. Always remove the batteries when not in use for an extended period to prevent self-discharge or corrosion. If the flashlight features a charging function, use the original charger that matches the device’s specifications to avoid battery damage. Regularly checking the voltage output and replacing the batteries before they become too weak can prevent poor performance during critical tasks in your mechanic’s workshop. Flashlights For Mechanics should be treated as an investment; proper maintenance and care will ensure they are reliable tools when you need them most.

When working in the demanding environments of automotive and mechanical workshops, reliability is paramount. Flashlights for mechanics must withstand various challenges, including wet conditions that can hinder visibility and safety. This comprehensive article has delved into the necessity of waterproof flashlights, highlighting their key features, top-rated models, and the science behind their robust construction. Mechanics will find valuable insights on selecting the best flashlight for their needs, ensuring both durability and illumination in the most challenging situations. Regular maintenance and care are essential to maintain peak performance of these vital tools. In essence, a waterproof flashlight is an indispensable ally for any mechanic striving for efficiency and safety under any weather condition.