Flashlights for mechanics are essential tools designed to withstand the demanding conditions of automotive repair environments. These durable flashlights, typically constructed from high-impact resistant materials like aircraft-grade aluminum or titanium, feature shock resistance, reinforced bezels, and impact-resistant polycarbonate lenses. They offer adjustable brightness, including high-intensity LED options that simulate daylight, which is crucial for clarity and contrast in tight spaces. With features like waterproofing and dust sealing via premium silicone O-rings and gaskets, these flashlights ensure functionality across various environments. LED technology provides longer runtime on a single charge, energy efficiency, and longevity, making them a reliable and enduring choice for frequent use. The adjustable beams and robust design of Flashlights For Mechanics enhance precision and speed in tasks, offering targeted lighting that is indispensable for complex mechanical systems. They are compact enough to fit into confined spaces, such as under dashboards or within engine compartments, streamlining troubleshooting and repair processes, and ultimately saving time and minimizing errors during diagnostic work.

When precision meets darkness, the indispensable role of high-quality flashlights for mechanics comes into sharp focus. In confined spaces where visibility is as critical as the tools at hand, the right illumination tool can make all the difference. This article delves into the essential features of flashlights for automotive and machinery repair, emphasizing portability, ergonomic design, and robust construction to navigate and work effectively in tight quarters. We’ll compare LED versus halogen flashlights to understand their impact on efficiency and assess the importance of battery life and brightness for optimal visibility. Furthermore, we’ll explore practical applications that highlight how these tools facilitate diagnosis and repair tasks in enclosed areas, ensuring mechanics have a dependable light source for every job. Flashlights For Mechanics is your guide to illuminating the path to trouble-free repairs and enhancing mechanical precision.

- Understanding the Role of High-Quality Flashlights for Mechanics

- Key Features to Look for in a Flashlight for Automotive and Machinery Repair

- The Importance of Portability and Ergonomic Design in Confined Space Work

- Assessing Battery Life and Brightness for Optimal Visibility in Dark Environments

- Durability and Material Considerations for Long-Term Mechanical Use

- Advanced Technologies: LED vs. Halogen Flashlights and Their Impact on Efficiency

- Practical Applications: How Flashlights Facilitate Diagnosis and Repair in Enclosed Areas

Understanding the Role of High-Quality Flashlights for Mechanics

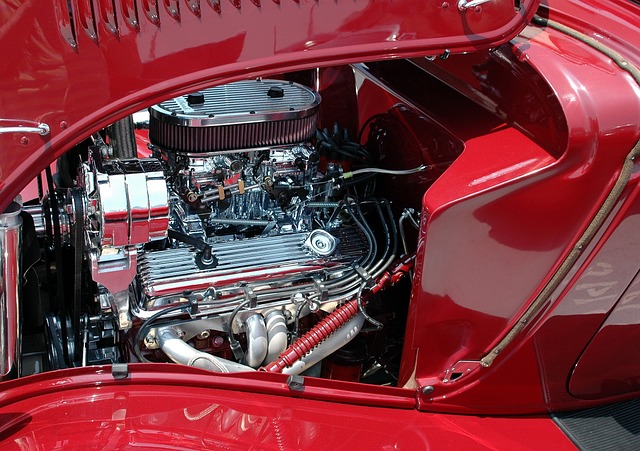

When it comes to diagnosing and repairing vehicles, mechanics often find themselves working in confined spaces where adequate lighting is crucial for precision and safety. High-quality flashlights, specifically designed for professionals, are indispensable tools in their trade. These flashlights for mechanics, typically featuring robust construction and high lumen output, provide the necessary illumination to reveal intricate components and tight corners within an engine or electrical system. Their durability ensures they can withstand the demanding conditions of a workshop environment, while their lightweight design allows for easy maneuvering in limited spaces. The intense beam of a high-quality flashlight not only brightens the work area but also helps mechanics to identify issues more quickly and accurately. Additionally, features such as multiple lighting modes—high, medium, and low beams—allow mechanics to conserve battery life when a dimmer light is sufficient or to focus a powerful spotlight exactly where it’s needed most. This adaptability, combined with the ability to withstand drops, dust, and vibrations, makes high-quality flashlights an essential component of a mechanic’s toolkit, enhancing both efficiency and effectiveness on the job.

Key Features to Look for in a Flashlight for Automotive and Machinery Repair

When selecting a flashlight for automotive and machinery repair, durability and reliability are paramount due to the demanding environments mechanics often encounter. A robust construction ensures the flashlight can withstand drops, falls, or being accidentally run over by vehicles in the workshop. Look for flashlights designed specifically for mechanics, which typically feature high-impact resistant materials such as aircraft-grade aluminum. These flashlights are engineered to operate under a range of temperatures and conditions, from sweltering engine bays to damp and oily environments.

Another critical feature is a high-intensity beam with adjustable focus. This allows mechanics to switch between a wide floodlight for general area illumination and a concentrated spotlight for examining tight or hard-to-reach spaces. LED technology is preferred for its longevity and energy efficiency, providing bright light without the bulk of older technologies. Additionally, features such as multiple lighting modes—high, low, and strobe—can extend battery life during routine work while offering a disorienting strobe for safety in emergency situations. For those who work with vehicles or machinery that are particularly dirty or hazardous, flashlights with IP ratings indicating water and dust resistance are essential. These flashlights will keep working even when exposed to the elements or when used around fuel sources. Finally, consider the ergonomics of the flashlight—a comfortable grip, a well-designed switch, and a secure pocket clip can make all the difference when working for extended periods. Flashlights For Mechanics that combine these features will prove invaluable tools for any mechanic’s arsenal.

The Importance of Portability and Ergonomic Design in Confined Space Work

When navigating through confined spaces, such as those encountered by mechanics working under vehicles or in compact work environments, the design and functionality of a flashlight become paramount. Portability is a critical aspect; a lightweight and compact flashlight allows for easy handling and maneuvering in tight quarters without adding bulk or weight to an already cramped workspace. The ability to reach every nook and cranny with a beam of light can mean the difference between identifying a minor issue before it becomes a major problem and overlooking something crucial.

An ergonomic design further enhances the practicality of flashlights for mechanics. A flashlight that fits comfortably in the hand, with a grip that doesn’t slip when covered in grease or oil, is essential. Additionally, features like an anti-roll design, pocket clips, and strap attachments ensure that the light is always accessible when needed. Ergonomic switches that can be activated with minimal effort, even with gloves on, prevent the interruption of precise work to adjust lighting conditions. Such considerations in a flashlight’s design facilitate uninterrupted focus on the task at hand, making it an indispensable tool for any mechanic working in confined spaces. Flashlights designed with these features in mind are not just accessories but integral components of a mechanic’s kit, ensuring efficiency and safety during complex troubleshooting and repairs.

Assessing Battery Life and Brightness for Optimal Visibility in Dark Environments

When selecting a flashlight for troubleshooting in confined areas, particularly for mechanics, assessing battery life and brightness is paramount to ensure optimal visibility in dark environments. A flashlight with a long-lasting battery is crucial for sustained use during lengthy repair jobs. Mechanics often work in spaces where light sources are limited, making the reliability of the flashlight’s battery indispensable. High-quality flashlights for mechanics are designed to provide consistent lumen output over their operational time, allowing for precise work and reducing the interruptions caused by frequent battery changes.

In terms of brightness, a flashlight equipped with a high-intensity beam is essential for mechanics to clearly see intricate components and fine details that could be critical to the task at hand. The brightness level should be adjustable to adapt to different scenarios, from inspecting deep crevices to checking under hoods where direct light may be reflective. Flashlights for mechanics often come with LED technology, offering a balance between energy efficiency and powerful illumination. This technology ensures that the light emitted is focused and penetrates through the darkest corners, aiding in the swift identification of issues and preventing oversight due to poor visibility.

Durability and Material Considerations for Long-Term Mechanical Use

When mechanics delve into the intricacies of troubleshooting in confined spaces, the reliability and robustness of their flashlights cannot be overstated. A flashlight for mechanics is subject to rigorous use, often in environments where it may encounter falls, impacts, or exposure to dust and moisture. To ensure longevity and consistent performance, these flashlights must be constructed from durable materials such as high-grade aluminum or aerospace-grade titanium. These materials not only provide the necessary strength to withstand the demands of a mechanic’s work but also keep the weight manageable for extended periods of use. Additionally, the design should incorporate shock-resistant features and a sturdy bezel to protect the lens from accidental bumps. High-impact polycarbonate lenses are preferable as they offer clarity and resistance to scratches and shocks, ensuring that the beam remains focused and visible under adverse conditions. The construction of O-rings and gaskets from premium silicone ensures both waterproofing and dust protection, which is crucial for maintaining the integrity of the flashlight in all environments. For mechanics who rely on these tools daily, a flashlight designed with such considerations is an indispensable companion that can endure the tests of time and use.

Advanced Technologies: LED vs. Halogen Flashlights and Their Impact on Efficiency

When it comes to selecting a flashlight for troubleshooting in confined areas, such as those encountered by mechanics, efficiency and reliability are paramount. The choice between LED and halogen flashlights significantly influences the efficiency of the task at hand. LED flashlights, like those designed for mechanics, have surpassed their halogen counterparts with advancements that offer several key benefits. Firstly, LEDs consume less power, providing a longer runtime on a single charge, which is crucial when working in areas without immediate access to electrical outlets. This energy efficiency also translates to a cooler operation, reducing the risk of overheating and ensuring a safer working environment.

Moreover, LED flashlights offer superior brightness and focus capabilities. The technology behind LEDs allows for a more concentrated beam that can illuminate dark spaces with clarity, making it easier for mechanics to identify intricate details or hidden issues within an engine or mechanical system. The longevity of LED lights also cannot be overlooked; they have a longer lifespan compared to halogen bulbs, meaning mechanics can rely on them for repeated use without the frequent need for replacements. This durability and consistent performance make LED flashlights an indispensable tool for professionals in the field, enhancing both speed and precision in their work.

Practical Applications: How Flashlights Facilitate Diagnosis and Repair in Enclosed Areas

Flashlights for mechanics serve as indispensable tools in diagnosing and repairing issues within confined spaces. Their compact size allows access to tight quarters where larger lighting solutions cannot fit. A robust flashlight can illuminate hard-to-reach areas under dashboards, hoods, or within engine compartments, enabling mechanics to pinpoint malfunctions with precision. The adjustable beams of modern flashlights allow for targeted lighting, which is crucial when the workspace is limited by the close proximity of components. Furthermore, high-intensity LED options provide a bright, clear light that mimics daylight, enhancing visibility and contrast for tasks such as inspecting wiring or checking fluid levels in cramped spaces. Flashlights designed for mechanics are often equipped with durable materials and impact-resistant designs to withstand the rigorous demands of professional environments. They are resistant to shock, water, and dust, ensuring that they maintain functionality even in the most challenging conditions. The combination of durability, versatility, and brightness makes flashlights an essential component in a mechanic’s toolkit, facilitating efficient troubleshooting and repair work in confined areas, thereby saving time and reducing errors during complex diagnostic procedures.

In conclusion, flashlights for mechanics are indispensable tools that enhance both precision and safety in troubleshooting confined areas. A high-quality flashlight, characterized by its robust construction, bright LED output, and reliable battery performance, is a critical asset for any automotive or machinery repair professional. Portability and ergonomic design ensure comfort during extended use, while advanced technologies like LED offer superior efficiency compared to halogen alternatives. When selecting a flashlight for mechanics, prioritize features such as durability, brightness, and battery longevity to optimize visibility in the darkest corners of your work environment. By doing so, you’ll be well-equipped to navigate even the most challenging repairs with confidence and clarity, making “Flashlights For Mechanics” not just a product category but a vital component of professional repair toolkits.