When selecting a flashlight for automotive repair, mechanics need a robust and reliable tool capable of withstanding tough workshop conditions. The best flashlights for this purpose are made from durable materials like aircraft-grade aluminum or impact-resistant plastics, ensuring they can endure drops without breaking. High lumen output is crucial for clear visibility in low-light areas, and a dual-function flashlight that offers both flood and spot beams allows mechanics to adapt to various tasks seamlessly. Additionally, high-efficiency LEDs with multiple power settings extend battery life, which is essential for long working hours. Features such as magnetic bases, rapid charging capabilities, red or green LED options for detail work, and lens filters for light intensity adjustment enhance the utility of flashlights in a mechanic's daily tasks. These specialized features make flashlights for mechanics indispensable tools that not only illuminate dark spaces but also contribute to a safer and more efficient working environment.

When precision is paramount and visibility wanes, the right flashlight becomes an indispensable tool for any mechanic. This article illuminates the critical role of efficient lighting in mechanical workshops, emphasizing the necessity of high-quality flashlights designed specifically for low-light conditions. We will explore key features that distinguish ‘flashlights for mechanics’ from general-purpose models, including lumens output, beam distance, and durable construction. Additionally, we’ll delve into battery types and runtime to ensure your light endures the longest jobs. With a focus on enhancing mechanical tasks, this guide will also highlight valuable accessories that elevate the functionality of these essential tools.

- Understanding the Importance of Visibility in Mechanical Workshops

- Key Features to Look for in Flashlights for Mechanics

- Top-Rated Flashlights for Low-Light Conditions Suitable for Mechanics

- The Role of Lumens and Beam Distance in Professional Maintenance Tasks

- Battery Types and Runtime Considerations for Long Hours of Maintenance Work

- Durability and Impact Resistance: Ensuring Your Flashlight Stands Up to the Demands of Mechanical Jobs

- Accessories and Additional Features That Complement Mechanic-Grade Flashlights

Understanding the Importance of Visibility in Mechanical Workshops

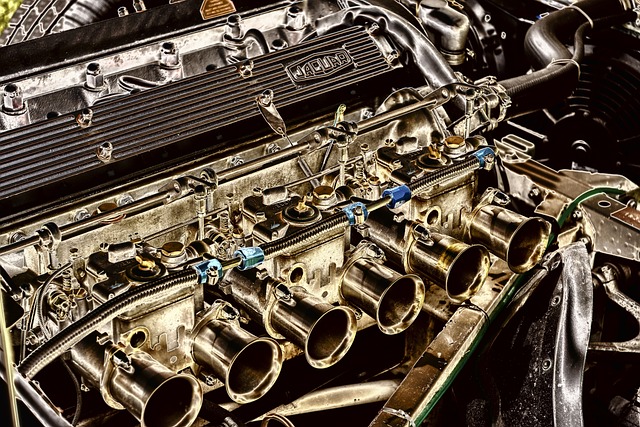

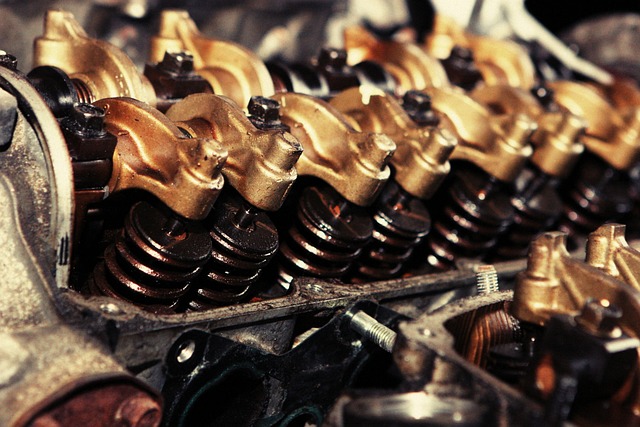

In mechanical workshops where precision and clarity are paramount, visibility becomes a critical component of effective maintenance work. The right lighting can significantly enhance a mechanic’s ability to see fine details on machinery, which is crucial for ensuring the safety and functionality of vehicles or equipment. Flashlights for mechanics are engineered to deliver intense beams that penetrate low-light environments, offering high-contrast illumination where it’s most needed. These tools are designed with durable construction and ergonomic grip, ensuring that they can endure the demanding conditions of a workshop while providing stable light for prolonged periods. The strategic placement of flashlights for mechanics allows users to highlight specific areas, such as tight spaces or hard-to-reach components, without causing shadows or glare that could otherwise obscure critical details. Selecting flashlights with features like adjustable focus, LED technology, and various brightness settings empowers mechanics to adapt their lighting to any task, from inspecting a car’s engine to diagnosing electrical issues in the darkest corners of a vehicle. Incorporating flashlights for mechanics into the daily routine of maintenance work not only optimizes efficiency but also supports the accuracy and quality of repairs and maintenance tasks.

Key Features to Look for in Flashlights for Mechanics

When selecting a flashlight tailored for mechanics working in low-light conditions, several key features stand out as particularly beneficial. Firstly, durability and robustness are paramount, as mechanics often operate in challenging environments where the flashlight may be subjected to drops, vibrations, and exposure to dust and debris. A flashlight constructed with high-quality materials such as aircraft-grade aluminum or a rugged polymer can withstand these conditions. Additionally, it should possess an impact-resistant design to ensure continued functionality even after accidental impacts.

Secondly, lumen output is a critical factor for clarity and working visibility. High-lumen flashlights, particularly those offering over 1000 lumens, are ideal for illuminating large work areas or focusing a beam on intricate tasks. Mechanics should also consider the beam type; a focused spotlight can be essential for targeting specific points, while a wider flood beam is better suited for general area lighting. Features such as adjustable focus, multiple brightness levels, and energy-efficient LED technology will further enhance the versatility of the flashlight in various maintenance scenarios. Battery life and rechargeability are also significant considerations, as mechanics often work for extended periods in low-light conditions, necessitating a reliable power source. Flashlights equipped with long-lasting batteries or capable of being powered by multiple energy sources, such as AA/AAA batteries, rechargeable lithium-ion, or USB charging, are particularly advantageous for this profession.

Top-Rated Flashlights for Low-Light Conditions Suitable for Mechanics

When mechanics encounter low-light conditions, whether in a dimly lit garage or under the hood of a vehicle at dusk, having a reliable flashlight is paramount. The best flashlights for mechanics are not just about raw lumens; they must offer a balance of brightness, battery life, durability, and user-friendly features that can withstand the demands of a mechanic’s work environment. Top-rated models like the Streamlight 61009 ProTac HL are engineered with a high-intensity beam capable of cutting through darkness, featuring a C4 LED that provides a powerful output suitable for close-up tasks as well as distant inspections. Its adjustable intensity allows users to toggle between a floody light for wide coverage and a focused beam for precise work. Another favorite among professionals is the Milwaukee 234022 M18 FUEL LED Headlamp, which offers hands-free illumination with its adjustable headband. This model stands out due to its high-performance rechargeable lithium battery pack and the ability to withstand tough job site conditions. Its spotlight and floodlight settings make it ideal for tasks that require both focused and widespread lighting, making it a versatile tool for any mechanic’s arsenal. Additionally, flashlights like the Boston Cop FL-5Tac or the EverBrite EB1025R offer high-quality illumination with features tailored to the needs of mechanics, such as impact resistance, waterproofing, and long battery life, ensuring that even in the most challenging low-light conditions, mechanical work can proceed efficiently and safely.

The Role of Lumens and Beam Distance in Professional Maintenance Tasks

When selecting a flashlight for professional maintenance tasks, particularly in low-light environments such as those encountered by mechanics, understanding the role of lumens and beam distance is crucial for optimal performance. Lumens, which measure the total amount of light emitted from a source, dictate the brightness of a flashlight. For tasks that require precision work under hoods or in confined spaces, a higher lumen output ensures objects are clearly visible, reducing the risk of misdiagnosis and improving efficiency. Mechanics need a beam that not only illuminates their immediate surroundings but also extends far enough to inspect components at a distance without losing clarity. This is where beam distance becomes equally important. A long-distance beam allows mechanics to identify issues on parts that are further away, such as checking the integrity of wiring or inspecting the underside of vehicles.

Flashlights For Mechanics should therefore feature a well-balanced blend of high lumens and effective beam distance. A flashlight with a flood illumination type might be preferable for tasks up close, while a spot beam is beneficial for distant object inspection. Additionally, features like adjustable focus, which can switch between a wide, close-range flood and a narrow, long-distance spot, provide versatility and adaptability to different situations on the job. Durability and ergonomic design are also significant considerations, ensuring that the flashlight remains operational under the demanding conditions of a mechanic’s workspace and is comfortable to hold for extended periods. By prioritizing these features, professionals can maintain visibility and perform their duties with precision and safety in low-light conditions.

Battery Types and Runtime Considerations for Long Hours of Maintenance Work

When engaging in low-light maintenance tasks, mechanics require flashlights that are not only reliable but also capable of providing ample illumination for extended periods. The choice of battery type in flashlights for mechanics is pivotal for ensuring long hours of uninterrupted work. Lithium-ion (Li-ion) and lithium-polymer (LiPo) batteries are preferred for their high energy density, long life, and lightweight properties. These batteries offer a consistent output over time, which is essential when working in challenging environments where visibility is critical. Users should consider the battery’s capacity, measured in milliampere-hours (mAh), to determine the runtime based on the flashlight’s lumen output. A higher mAh rating typically translates to a longer run time, making it ideal for tasks that may last several hours. Additionally, the ability to quickly recharge the battery without compromising performance is a valuable feature for mechanics who need to conserve power during long jobs.

Runtime considerations are equally important when selecting a flashlight for maintenance work. High-quality flashlights designed for professionals often come with multiple modes to optimize battery usage, including low, medium, and high settings. The low-power mode extends the battery life significantly, allowing mechanics to maintain visibility throughout complex tasks without the urgency of conserving power. It’s also advisable to opt for flashlights that use high-efficiency LEDs, as they consume less energy and generate less heat compared to traditional bulbs. This not only prolongs the runtime but also ensures a safer working environment. For the best performance, mechanics should invest in flashlights specifically designed for ‘flashlights for mechanics,’ which are engineered to meet the demands of professional use in low-light conditions.

Durability and Impact Resistance: Ensuring Your Flashlight Stands Up to the Demands of Mechanical Jobs

When selecting a flashlight for low-light maintenance tasks, especially within mechanical contexts, durability and impact resistance are paramount. Mechanics often work in environments where tools and equipment are subject to rough handling and accidental drops. Flashlights for mechanics must be engineered to withstand such conditions without fail. High-quality flashlights designed for this purpose typically feature a robust construction, utilizing materials like aircraft-grade aluminum or impact-resistant plastics that can endure repeated and harsh impacts. These materials not only protect the internal components from damage but also ensure the device remains functional even after an unintended fall from a work platform or toolbox shelf.

Furthermore, the best flashlights for mechanics are built to operate reliably in a variety of temperatures and conditions, ensuring that they provide consistent illumination when needed most. Impact resistance is also gauged by standards like the Military Standard 810G, which tests for drops onto hard surfaces from various heights. A flashlight that has passed these rigorous tests will serve as a reliable companion through long hours of work in dimly lit spaces, under vehicle hoods, or inside confined areas where mechanical repairs are conducted. The combination of durability and impact resistance in flashlights for mechanics is crucial for their longevity and dependability, making them an indispensable tool in the arsenal of any professional mechanic.

Accessories and Additional Features That Complement Mechanic-Grade Flashlights

When selecting a flashlight for low-light maintenance tasks, mechanics often prioritize durability, brightness, and features that enhance visibility in the toughest environments. To complement mechanic-grade flashlights, several accessories and additional features are indispensable. Firstly, lens filters can be crucial for adjusting light intensity to suit different work conditions; they allow mechanics to switch between a narrow beam for distant objects and a wide flood for close-up tasks. Magnetic bases or built-in magnets are also highly beneficial, as they secure the flashlight to metal surfaces, freeing up a mechanic’s hands while ensuring the light remains precisely where it’s needed. High-capacity rechargeable batteries with quick-charging capabilities ensure that the light source never fails when operating in challenging conditions. Additionally, impact-resistant coatings or housings are essential for protecting the flashlight from the rigors of a working environment, preventing damage from falls or tool collisions. For those who frequently work in teams, models with multiple user interfaces can facilitate better coordination, allowing mechanics to signal or communicate with one another without verbal communication. Lastly, flashlights designed specifically for mechanic use often come with features such as red or green LEDs, which are less harsh on the eyes and ideal for inspecting fine details or reading small print on schematics in low-light conditions. These additional features and accessories make mechanic-grade flashlights not just tools but reliable partners on the job.

When it comes to executing maintenance tasks in low-light environments, the right flashlight is indispensable for any mechanic. As explored throughout this article, ‘Flashlights for Mechanics’ are not just tools; they are critical partners that ensure visibility and precision during intricate repairs. Key factors such as lumens output, beam distance, battery longevity, and durability are paramount to optimize performance and reliability. By considering the featured flashlights and their additional features, professionals can select models that meet their specific needs, enhancing both efficiency and safety. In essence, for those working in low-light conditions, a robust, high-quality ‘Flashlight for Mechanics’ is not just a luxury but a necessity, transforming the workspace into a well-illuminated area conducive to meticulous workmanship.